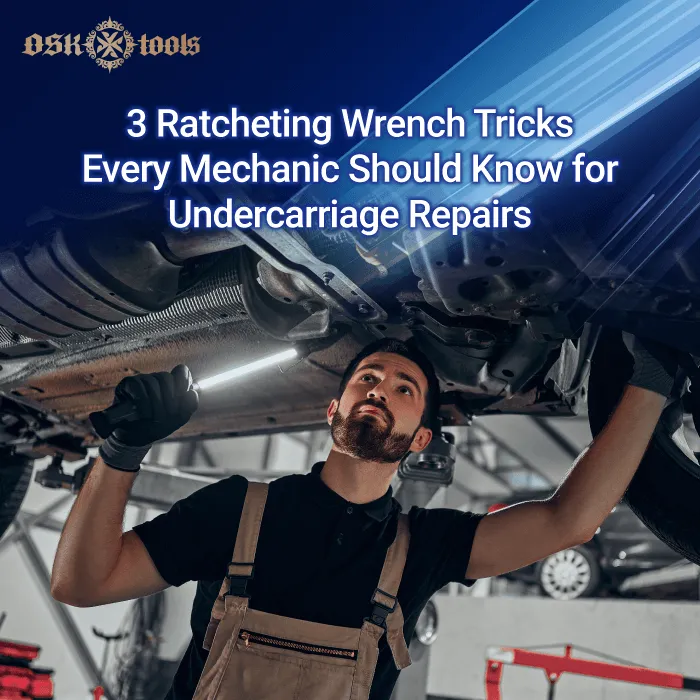

When it comes to undercarriage repairs, few things are more frustrating than dealing with stubborn bolts in tight, awkward spaces. Lying beneath your vehicle with limited room to move, even simple tasks can become difficult. That’s where a good ratcheting wrench becomes your best friend. In this article, we’ll share 3 practical ratcheting wrench tricks that can help you complete undercarriage repairs more efficiently—even without a trip to the shop.

- Ratcheting Wrench Tricks for Undercarriage Repairs▼

- Recommended OSK Vehicle Maintenance Wrenches: Complete Size Options for All Your Repair Needs▼

Ratcheting Wrench Tricks for Undercarriage Repairs

Whether you’re a professional mechanic or a hands-on car owner, knowing how to use a ratcheting wrench the right way can significantly improve your undercarriage repair process—both in terms of safety and efficiency. Especially when dealing with rusted or deeply hidden bolts, using the right tool with the right technique makes all the difference. Let’s explore 3 tried-and-true ratcheting wrench tricks that will help you tackle common undercarriage repair challenges with confidence.

1.Use a Flex-Head Ratcheting Wrench for Angled Access

Undercarriage repairs often involve bolts positioned at awkward, hard-to-reach angles—such as those on suspension arms, exhaust hangers, or driveshaft flanges. These bolts are typically located in tight spaces where a straight wrench can’t align properly, making it difficult to apply force without straining your wrist or risking injury.

A flex-head ratcheting wrench solves this problem by allowing the head of the wrench to pivot at different angles. This design enables the user to match the wrench head to the bolt’s axis, even in severely restricted spaces. It reduces the need to reposition your body or tool constantly, and minimizes the risk of hand fatigue or accidental slips.

Further reading:What is the benefit of a flex head ratchet? 4 benefit you should know

For DIYers working without a lift—lying flat on the ground—this flexibility becomes even more valuable. The ability to reach tricky bolts from side angles or below with minimal clearance makes the flex-head ratcheting wrench an essential tool for efficient and safe undercarriage work.

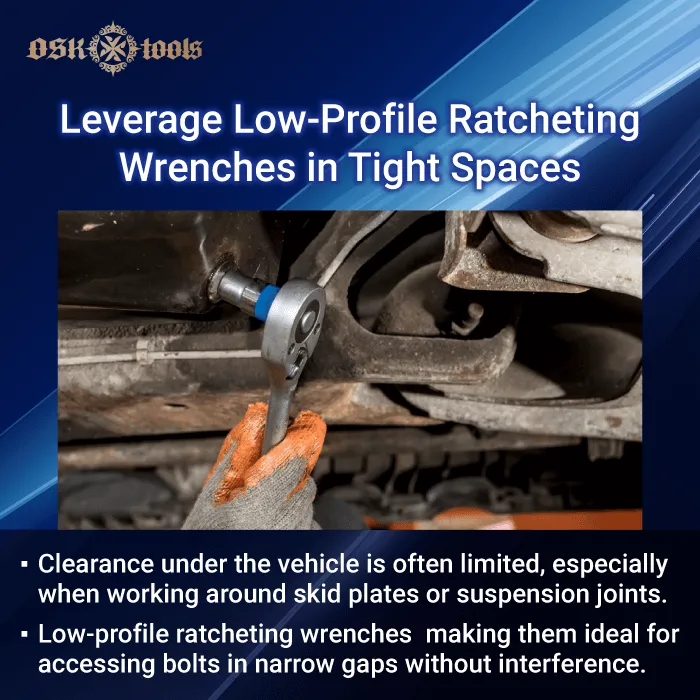

2.Leverage Low-Profile Ratcheting Wrenches in Tight Spaces

When working under a vehicle or in engine compartments, one of the biggest challenges is limited space. Areas around the subframe, exhaust brackets, or oil pan edges are often too tight for standard tools to fit or rotate. That’s where a low-profile ratcheting wrench becomes indispensable.

These wrenches feature an ultra-slim design that not only retains the ratcheting mechanism but also significantly reduces the head and body thickness, allowing access to bolts that would otherwise be unreachable.

Common Use Cases

- Around exhaust system brackets: tight and heat-sensitive zones

- Bolts near engine walls: where components are closely packed.

- Nuts between skid plates and subframes.

- Deep cavities where socket wrenches can’t reach.

Further reading:3 Essential Vehicle Repair Wrenches for Motorcycle Maintenance

3.Combine a Ratcheting Wrench with a Cheater Bar for Extra Torque

In undercarriage repairs, it’s common to face bolts that are rusted, overtightened, or seized after years of use. While a ratcheting wrench is helpful, sometimes hand strength alone isn’t enough to break these stubborn fasteners loose. That’s where using a cheater bar becomes a game-changer.

Safety Tips

- Avoid using on plastic or aluminum parts to prevent thread or component damage.

- Use a heavy-duty ratcheting wrench with a strong handle to avoid tool breakage.

- Wear gloves and ensure stable footing and control to prevent slipping or injury.

When used correctly, combining a cheater bar with a ratcheting wrench greatly improves your mechanical advantage, helping you tackle tough bolts efficiently while minimizing physical strain.

Recommended OSK Vehicle Maintenance Wrenches: Complete Size Options for All Your Repair Needs

Mastering these three ratcheting wrench tricks can make undercarriage repairs safer, smoother, and far more efficient. Choosing the right tool makes all the difference. If you're looking for a wrench that stands up to real-world demands, OSK Tools’ ratcheting wrenches—featuring a rust-resistant black chrome finish and proven durability through 96-hour salt spray testing—are a smart investment. Whether you're a weekend DIYer or a daily mechanic, OSK is the reliable partner your toolbox deserves.

Released on 2025-06-06|Last updated on 2025-06-19 | 838

OSK Tools-Wrench Brand

Phone: +1 949 372 2831(Click to call)

Facebook:OSK Tools(Click to visit)

FB Messenger:OSK Tools(Click to DM)

Service Time: 09:00-18:00 on weekdays